Equipment company

- Categories:Subsidiary

- Time of issue:2020-05-13 00:00:00

- Views:0

Description:

Information

Hubei Bird King Intelligent Equipment Co., Ltd. was established in 2018 with a registered capital of 5 million yuan. The company is headquartered in Donghu New Technology Development Zone, Wuhan City, Hubei Province, and has a 3000 square meter equipment manufacturing plant in Anlu City, Hubei Province. The company is mainly engaged in the research and development, production and sales of intelligent poultry farming equipment, electromechanical integration egg processing equipment, and farming waste treatment equipment. The company has strong design and manufacturing capabilities, and can customize various egg processing and breeding equipment for users according to customer needs. At present, it has developed a poultry and egg manipulator for large domestic breeding and egg processing companies such as Hubei Shendan Health Food Co., Ltd. Automatic feeding equipment, continuous cooking-cooling-air-drying-shell peeling production line for sweetheart eggs (poached egg), multi-row egg washing machine, salted duck egg beater, salted egg yolk dryer, automatic packing-sealing packaging production line, Egg product pressure and temperature rapid curing equipment, egg high-efficiency hole-opening machine, preserved egg bagging bran machine, household intelligent water bath heating egg cooker, egg and duck stacked cage equipment, breeding duck ladder breeding equipment, egg duck welfare breeding equipment , More than 20 solar photovoltaic greenhouse duck raising equipment, light egg collection line, poultry breeding pre-car, intelligent manure fermentation turning machine, vertical manure high temperature fermentation tower, horizontal manure fermentation and drying integrated equipment, etc. The main products of this category are automated quail breeding cages, salted egg yolk production lines, etc. The products have reliable quality, stable operation, and timely after-sales service, which are well received by users.

Public company: Hubei Bird King Intelligent Equipment Co., Ltd.

Address: No. 888 Gaoxin Avenue, East Lake New Technology Development Zone, Wuhan

Postcode: 430206

words: 86 27 87399645

Biography True: 86 27 87399645

Mobile phone: 13986165641

Mail box: 438664286@qq.com

Contact : Mr. Wang

QQ : 438664286

WeChat: wangxiansheng612936

Company website: http://www.hubeiniaowang.com

High-end quail layered breeding equipment

The company's self-developed stacked quail cage breeding equipment has the functions of automatic metering and supply of feed, water supply, light, automatic egg collection, vertical, horizontal, and oblique three directions of automatic manure removal, fan and wet curtain, and automatic house environment control. The high degree of automation saves a lot of labor costs for breeding enterprises. In terms of design, it inherits and absorbs the advantages of layered cages for laying hens, and at the same time overcomes the deviation of manure belts, water line leakage, high egg breakage rate, large feed waste, and small size of the common breeding cages. It is easy to run out of cage nets, poor ventilation, high mortality, etc. Through special design and innovation (China Patent: 20121045831.3; 201220630604.0), it is more suitable for the quail's body characteristics and living habits, and provides a comfortable living environment for egg quails; On the top, 275g high-quality galvanized steel sheet is used as the structural material, all sheet metal technology, no welding point connection, to ensure the corrosion resistance performance and service life of the equipment to the greatest extent; at the same time without welding deformation, high manufacturing accuracy, neat and beautiful equipment. The company has provided more than ten quail breeding equipment to the breeding department of Hubei Shendan Health Food Co., Ltd. After five years of breeding practice, the egg production rate is high, the feed waste is low, the equipment is easy to operate, the failure rate is low, and it is deeply received by the breeding personnel Good reviews.

Common stacked quail breeding equipment

In order to meet the needs of small and medium-sized quail farmers and those who are new to the quail farming industry, and further reduce the investment in breeding equipment, the company has specially developed an ordinary laminated quail breeding equipment. By simplifying the structure, the screw feed is used to replace the feed tank and other measures. The equipment cost is greatly reduced. However, Renran has basic functions such as automatic fecal cleaning and automatic feeding.

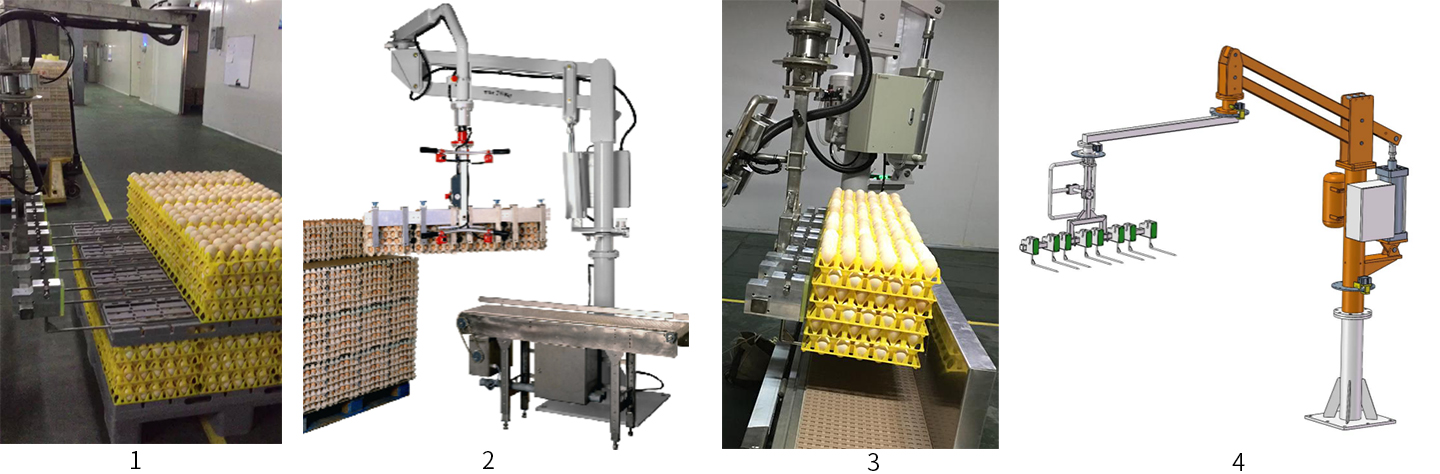

Figure 1. Egg feeding operation of power-assisted robotic hand (insertion) Figure 2. Egg feeding operation of power-assisted robotic hand (hanging) Figure 3. Egg feeding operation of power-assisted robotic hand (put down) Figure 4. Three-dimensional design scheme of egg feeding robotic arm

Continuous Sweetheart Eggs (Sweetheart Eggs) Production Line

The use of mass and heat transfer theory and finite element temperature field analysis technology overcomes the technical problems of individual differences in eggs and the difficulty of accurately controlling the steam temperature in the open system of continuous cooking equipment. Water bath heating is used to achieve precise temperature control; rotary centering is used , Solve the technical problem of eccentricity in egg protein and yellow gel, resulting in uneven heating of the egg yolk powder and protein easy to break when peeling; relying on a number of unique mechanical and electrical integration technical measures to ensure sweetheart and softheart products Quality consistency and product quality stability. The production line has an output of 5000 pieces/hour, and the breakage rate is less than 1%. Through the adjustment of temperature and heating time, it can produce shelled sweetheart eggs, shelled soft-boiled eggs, shelled soft-boiled eggs, fully cooked white boiled eggs and other products ; Can form a variety of production lines with feeding system, shelling machine, etc.

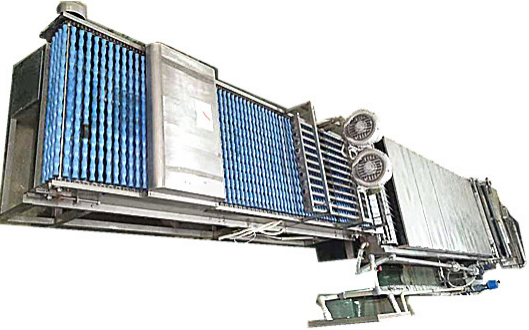

Water bath heating continuous sweetheart egg boiled egg production line (cooling and sorting section)

Water bath heating continuous sweetheart egg boiled egg production line (water bath heating section)

Egg washing machine

The machine adopts water feeding, and the three rows are cleaned at the same time after separation, and the efficiency reaches 20,000 pieces/hour. A special brush is used to clean the eggs from 4 angles in the direction of the long axis of the eggs. Combined with the rotation of the eggs, the pickled salted or fresh duck eggs can be cleaned in all directions without dead corners, avoiding the eggs that cannot be washed by other products on the market. Disadvantages at both ends. Clean and low damage rate. The machine can be connected to subsequent air-drying, testing and grading equipment to form a salted duck egg processing production line, realizing the modernization of the production of traditional egg products.

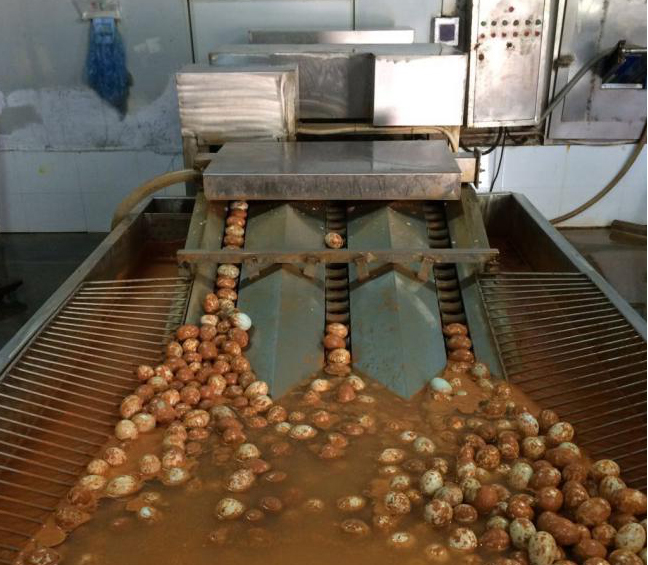

Three-row egg washing machine (feeding in water)

Three-row egg-washing machine (complete machine)

Laying duck layering, ladder cage equipment

Laying duck breeding cages are our company's reference to domestic and foreign laying hen layer cage breeding equipment. Based on long-term observation of laying duck habits and a large number of experiments, the company has independently innovated. The environmental protection of this system is of great significance. It only needs to supply drinking water through nipples, which subverts the traditional duck-raising mode in which ducks cannot live without water, and avoids water pollution in ponds and lakes. The breeding efficiency is high. A single building can raise more than 20,000 egg ducks, and multiple buildings can be connected. It is composed of fully enclosed wet curtain, fan ventilation system, cage frame, cage net system, automatic fecal cleaning system, automatic egg collection system, automatic feeding system, LED energy-saving lighting system and control system, with a high degree of automation. The equipment is made of 275g high-quality galvanized steel plate and high-strength engineering plastics. It has good anti-corrosion and anti-aging properties and is durable. Using this system to breed laying ducks, the egg production rate is higher than that of flat laying ducks, especially not affected by the low temperature and cold in winter and the high temperature and heat in summer. The feed consumption rate is low, the duck eggs are clean, the damage rate is low, the duck feathers are eliminated, and the appearance is good.

Three-dimensional design model of layered laying duck cage equipment

Steel-concrete structure pressure and temperature control high-efficiency curing room equipment

Aimed at the problems of long curing period of traditional egg products, high labor intensity, high breakage rate, low labor efficiency, etc., a set of steel and concrete structure pressure and temperature control efficient curing device was developed. The system consists of a steel mixed structure pickling room with stainless steel plates in the inner village, a pipeline pumping system, a heating system and a PLC control system. The system can realize liquid inlet, liquid outlet, pressurization, decompression, pressure pulsation circulation and temperature Control, internal circulation of pickling fluid and external circulation of pickling fluid. The device has the following functions: (1) The curing room can automatically adjust the working pressure in real time by the program within the pressure range of -100kPa~250kPa according to the technological requirements; (2) During the curing process, it can be in the range of ambient temperature to 50℃ According to the technical requirements of the process, the temperature is automatically adjusted by the program in real time; (3) The pickling liquid in the pickling room can be automatically realized by the pump under the control of the program, such as the infusion, outflow, rehydration and internal and external circulation; (4) the system It can run automatically in the whole pickling cycle according to the set process plan; during the pickling process, the liquid can be drawn out at any time, and the door can be opened for sampling and detection; (5) poultry eggs to be cured and mature poultry eggs can be in and out In the pickling room, the track in the room can be docked with the external feeding track; (6) The pickling liquid can be pumped back to the mixing tank to adjust the concentration, sterilization, filtration and repeated use.

Left: Steel-concrete structure pressure and temperature control high-efficiency curing room (front and side) Right: PLC control system

>

The first one is: salted duck egg beater, central egg collection line;

The last two are: automatic packaging into the box, sealing production line

Salted egg yolk dryer

Scan the QR code to read on your phone

Copyright: Hubei Shendan Health Food Co., Ltd OA login link of Shendan internal office platform E-ICP:05013401 Powered by www.300.cn