27

2016

-

10

[2016 Ingenuity Chu Taste] National Internet Media Focus on Shendan Cleaning Egg Sales Pre-break 0.3 billion

Classification:

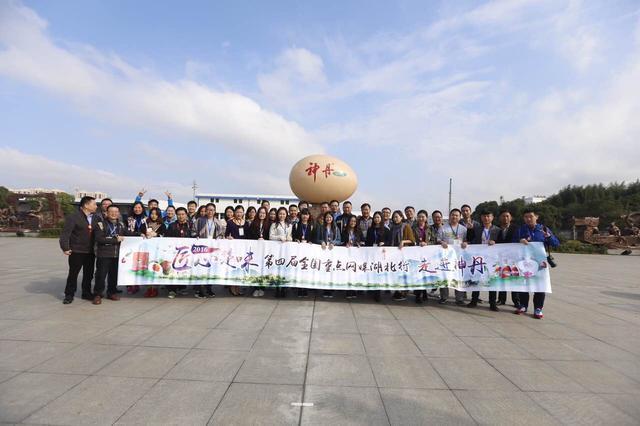

"Eggs also need a bath." On October 25, the national mainstream network media participating in the activity of "2016 ingenuity, chuwei, 4th national key network media trip to Hubei" entered Shendan, the leading company of Hubei egg products, and felt how the company drove Hubei's traditional food culture through modern skills.

![[2016 Ingenuity Chu Taste] National Internet Media Focus on Shendan Cleaning Egg Sales Pre-break 0.3 billion [2016 Ingenuity Chu Taste] National Internet Media Focus on Shendan Cleaning Egg Sales Pre-break 0.3 billion](https://omo-oss-image.thefastimg.com/portal-saas/new2023082522101523839/cms/image/72f3cd92-bddc-4281-a2c4-be5afdbd953d.jpg)

"Eggs also need a bath." On October 25, the national mainstream network media participating in the activity of "2016 ingenuity, chuwei, 4th national key network media trip to Hubei" entered Shendan, the leading company of Hubei egg products, and felt how the company drove Hubei's traditional food culture through modern skills.

The national network media entered the Shendan production workshop, and the full-automatic egg feeder was busy actively adsorbing fresh eggs to the production line. After eight processes, such as cleaning and drying, ultraviolet sterilization, oil coating, fresh-keeping, removing scattered yellow eggs, removing cracked eggs, weighing and grading, code spraying, packaging and forming, the "clean eggs" were able to pass the factory.

"Every egg has an ID card, all of which can be found online." Staff said that the spray code on the cleaning egg is its ID card. Through retrospective inquiry on Shendan official website, relevant information such as the breeder, breeding type and production batch of the cleaning egg can be found.

The reporter learned that ordinary eggs have dirt on the outside, which can easily lead to salmonella and E. coli poisoning. As early as 1970, the U.S. Congress deliberated and passed the "Egg Products Inspection Act", which listed dirty eggs as "dirty eggs" and destroyed the "dirty eggs" found on the market. Japan, Australia and other developed countries Most of the eggs sold in the country are also "clean eggs". In 2005, Shendan Company took the lead in introducing a cleaning egg production line in China. Eggs need to go through eight processes such as cleaning, drying and ultraviolet sterilization before they can be packaged and listed. At present, 270000 eggs are produced at the production line.

In 2009, Shendan Company, together with the National Egg Processing Skills Research and Development Sub-center, drafted China's first "Local Standard for Egg Cleaning". For the first time, Shendan Company introduced a new concept of egg health spending nationwide and began to integrate with the world.

At present, Hubei processes 240000 tons of clean eggs every year, accounting for 30% of the national clean egg output value. Hubei leads the country in terms of primary processed commodities such as "clean eggs" and "healthy eggs", which lead the promotion of spending concepts, and in-depth finished products such as egg powder, egg drinks and egg biochemical products. "It is estimated that the sales amount of cleaning eggs will reach 0.3 billion yuan in 2016."

Cleaning eggs is a microcosm of God Dan's insistence on manipulating food safety through the whole industry chain. Over the years, Shendan has been controlling all levels from egg and poultry breeding to feeding and promotion, from feed production to egg processing and selling. In terms of egg and poultry species, Shendan maintains close cooperation with scientific research institutions such as the Chinese Academy of Agricultural Sciences, Hubei Academy of Agricultural Sciences, and Huazhong Agricultural University, and is committed to developing patent species that are more suitable for Hubei's climate and safer and healthier.

At present, in addition to building 700000 high-standard modern egg and poultry farms, Shendan has also built farms with bases in Jingshan, Guangshui, Wuhan and other places in Hubei, raising more than 200 million eggs. For the cooperative breeding farm, Shendan will first strictly review its planning (more than 50000 laying hens and more than 3000 laying ducks), hardware equipment, personnel quality, etc. Only when the request is reached will the cooperative breeding agreement be signed, and two levels of supervisors will be set up to supervise and provide technical services to the cooperative farm.

[2016 Ingenuity Chu Taste] National Internet Media Focus on Shendan Cleaning Egg Sales Pre-break 0.3 billion

Previous Page